Is water jet cutting better than laser

Another consideration in tube cutting is the weld seam. This material is roll-formed and welded together. This brings up two points that typically must be addressed:

Helium

This is the most efficient solution for tubes of any length. Tubes up to O6" (152.4mm)2D cutCO2 and fiber laser

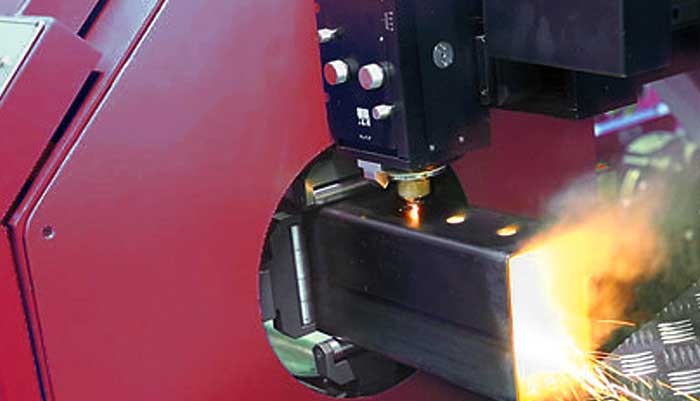

Even for XXL tubes, this machine is designed for maximum productivity. This machine is robust and solid-state laser capable of processing tubes and profiles of a wide variety of materials and wall thicknesses.

With Coherent laser systems, you can achieve precision in medical device manufacturing.

Save time and reduce the number of components.Make tubular frames and metal structures that are more precise and faster to assemble.Complete your part in one programming step, in one machining step, and on one system.

Another consideration in tube cutting is the weld seam. This material is roll-formed and welded together. This brings up two points that typically must be addressed:

At one time many thought that fiber lasers could be used only for thin materials. The CO2, with its larger wavelength, created enough kerf during the cutting of thick materials that enough space was allowed for material removal; the fiber laser couldn’t produce the same kerf or results with thicker materials. But that has been addressed in recent years with collimating technology that can produce a wider fiber laser-generated beam that creates materials separation and room for material removal in thick materials. And since the beam width is switchable, the machine can use the narrower beam to process thin materials, which allows for faster processing of different-sized materials on the same fiber laser cutting machine.

Large diameter profiles and tubes can be made with the fiber solution. Tubes up O 14 inches (355 mm).3D cutting modeFiber Laser

We haven't talked about cutting speed, you may have noticed. You can cut up to 500 inches per hour on a tube but it's not always possible. The main focus of laser tube cutting is how long it takes to load the tube, index it so that it's in the right spot for cutting, then pierce and slice it. Laser tube cutting machines have a slower cutting speed than they do with parts.

How can you compensate? Traditionally, you would touch the contact points by coming down. Next, rotate the tube and touch the opposite side. This will give the control an indication about how bent the tube may be. This can be used to ensure that through-holes fit the application. Be aware that this reduces your ability to deliver very precise tolerances every time the tube rotates.

The TruLaser Tube 5000 fiber is capable of reaching record speeds. It makes full use of solid-state Lasers' strengths. This results in shorter processing times for the user and a wider range of parts.

Laser cutting technology with shape can allow for complete customization. The raw material can be used to create finished or semifinished parts.

We are leaders in the production of advanced laser-cutting technologies, as well as CNC controls and automated systems.

Motion Dynamics, a world-class manufacturer of neurological parts, includes steerable catheters or "pullwire" assemblies. Motion Dynamics also makes use of StarCut Tubes for precision cutting key components.